The Best Modern Technology Inc

BM ELECTECH INC. has developed and manufactured the best quality products

in the field of the electric forklift's battery and battery charger.

Product

BM ELECTECH

- HOME

- Product

BMM Series

<Smart charger>

Functions and Benefits of the Smart Charger

Functions and Benefits of the Smart Charger

AUTO TAP

Tap is swiched automatically according to input voltage. Therefore, it is charged optimally without tap control.Optimization of the charge amount

Charging algorithm is applied for each DOD(Depth of Discharge) and prevents insufficient charge or overcharge due to equalized charge.Temperature Compensation

This is a function that prevents undercharging during cold seasons by implementing the low temperature compensating charge algorithm at an ambient temperature of 5°C or below.LCD Display (User friendly interface)

LCD screen on charger surface indicates electric current movement state of charger and information on charge and discharge.Charge History Management

History data on charge and discharge accmumulated for over 1,000 times is checked by LCD on the charger surface or PC. The data is used for general battery maintenance and for identifying the causes when problems occur.Quick Supplementary Charge

This is useful in businesses with heavy battery usage to increase the operational hours of the electric forklift.Equalizing Charge

Voltage and specific gravity deviations occur between battery cells when the battery is used for certain period of time. This feature corrects the deviations and makes each cell amount to be equal to maintain battery performance and to minimize life-shortening.Safety Function

This is a function that turns the power off and alerts the operator in the event of an overvoltage due to the aging of the battery, overheating of the charger, or a fault in the transformer or the rectifier.- Function to Prevent Battery Overvoltage

- Function to Cut off Electric Overcurrent

- Function to Detect Short-Circuit/Disconnection of the Transformer

- Function to Detect Overheating or an Error in the Transformer/Diode

Charger Specification

Charger Specification

| Model | Battery Voltage | Input Voltage | Chargeable Battery Capacity (Ah/5hr) |

|---|---|---|---|

| BMM 230 | DC 48V | AC 220V | 210-250 |

| AC 380V | |||

| AC 440V | |||

| BMM 295 | DC 48V | AC 220V | 280-335 |

| AC 380V | |||

| AC 440V | |||

| BMM 365 | DC 48V | AC 220V | 340-385 |

| AC 380V | |||

| AC 440V | |||

| BMM 460 | DC 48V | AC 220V | 400-490 |

| AC 380V | |||

| AC 440V | |||

| BMM 540 | DC 48V | AC 220V | 500-600 |

| AC 380V | |||

| AC 440V | |||

| BMM 650 | DC 48V | AC 220V | 610-690 |

| AC 380V | |||

| AC 440V | |||

| BMM 740 | DC 48V | AC 220V | 700-770 |

| AC 380V | |||

| AC 440V | |||

| BMM 840 | DC 48V | AC 220V | 800-870 |

| AC 380V | |||

| AC 440V |

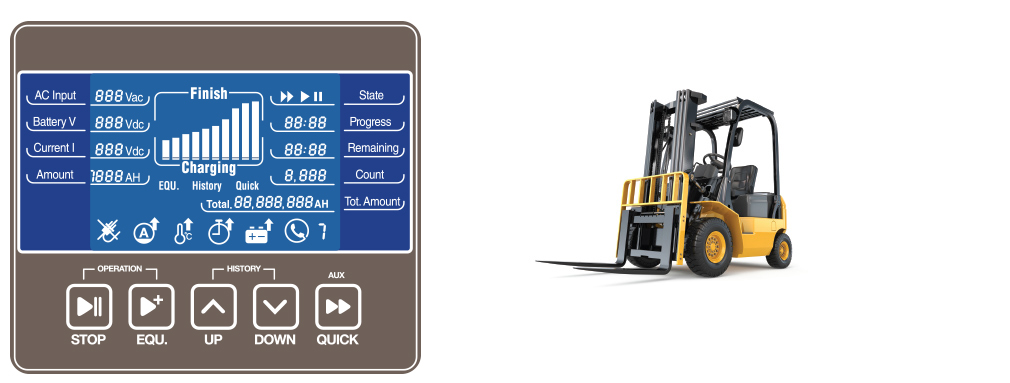

LCD Display [User friendly interface]

LCD Display [User friendly interface]

Operation Status

- Check on Input Power

- Check on Electric Current Status: Charge/Pause/Equalized Charge / Rapid Charge

Charging Status

- Battery voltage, electric current and charge amount can be checked in real-time during charging

Time Management

- Check the charging progress time and expected completion time

Estimating the Battery Life Time

- It predicts battery life through data on number of charging and accumulated charge data

Self-diagnosis on charger and battery

- Rapid and precise maintenance through LCD on charger surface when problem occurs on charger and battery

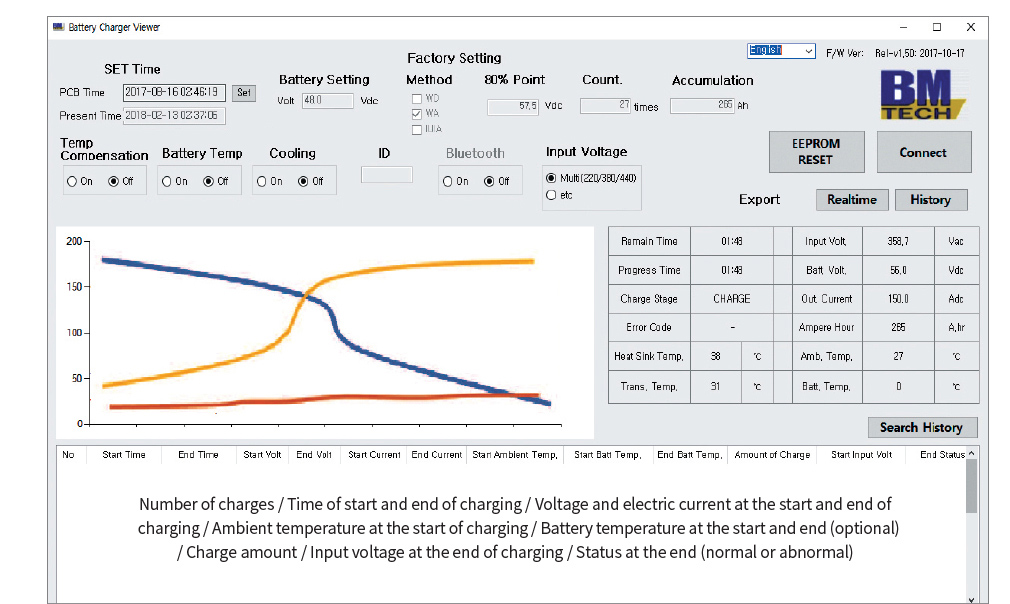

Charge Monitoring and History Management

Charge Monitoring and History Management

Data histories charged and discharged over 1,000 times can be inquired on the LCD screen of the charger and PC. Especially, when the charger is connected to PC, real-time charging status monitoring with details of historical data is available.

Viewing through an LCD

- 1. The “History Down or Up” button can be used after charging or during standby to check if the corresponding charging has been completed.

- 2. Viewable Items: Input voltage / Voltage and electric current at the end of charging / Charging time / Error event

Viewable using the proprietary history viewing program

- PC and control unit inside the charger are connected with USB serial cable and with dedicated Windows program, charging status and charge and discharge history can be checked in real time

State of charge can inquiry in real-time by using exclusive Windows U. I.

| Error Kinds |

Contents | Charge | Error code |

Action | Symbol | |

|---|---|---|---|---|---|---|

| Power |

Phase open | X | 0 | Automatic charging starts when the factor is removed | Fast flashing | |

| Blackout | X | 0 | Automatic charging starts when the factor is removed | Fast flashing | ||

| Voltage difference | X | 1 | Connect the battery after removing the factor | Fast flashing | ||

| Electric Current |

5A or under | X | 2 | Connect the battery after removing the factor | Fast flashing | |

| 300A or over | X | 3 | Connect the battery after removing the factor | Fast flashing | ||

| Temperature |

Inside | Low temperature | O | 4 | Continue charging | Slow flashing |

| High temperature | O | Connect the battery after removing the factor | Fast flashing | |||

| Heat Sink |

Need ventilation | O | 5 | Continue charging | Slow flashing | |

| Abnormal temperature | X | Connect the battery after removing the factor | Fast flashing | |||

| Trans | Need ventilation | O | 6 | Continue charging | Slow flashing | |

| Abnormal temperature | X | Connect the battery after removing the factor | Fast flashing | |||

| Timer |

Charging timeout | X | 0 | Connect the battery after removing the factor | Fast flashing | |

| Battery |

Low battery voltage at startup | X | 0 | Connect the battery after removing the factor | Slow flashing | |

| Low battery voltage during charging | X | 7 | Connect the battery after removing the factor | Fast flashing | ||

| Overvoltage during charging | X | Connect the battery after removing the factor | Fast flashing | |||

| Diode check | X | 9 | Connect the battery after removing the factor | Fast flashing | ||

| Reference |

No error code during normal operation. |

|||||

BMF Series

Introduction

Introduction

A battery charger is a device for charging electricity to batteries for electric forklifts by converting commercial AC power source to DC. Overcharging and undercharging due to excessive operation, irregular charging and discharging often causes shortening the life of batteries. This product, micom-controlled automatic charger, has supplemented such weak points and the semi-constant voltage/semi-constant current type battery charger adopting a leakage transformer enables high efficiency performance.

Property

Property

Multi-functions of this product have been automated by an 8-bit micom mounted digital system.

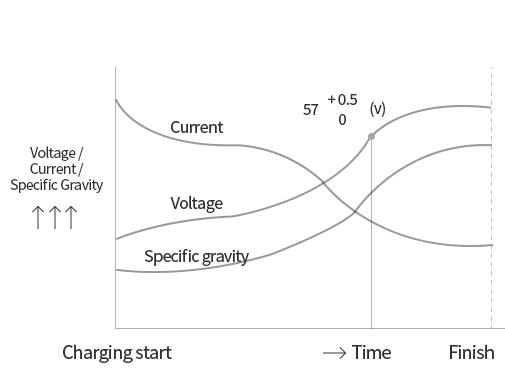

Conditions of Full Charging

- 1Micom completes the charging by detecting an output voltage and deciding the amount of charge that is automatically corresponded to the amount of discharge (About 8 hours of charging, in case of 80% charging)

- 2Automatic extended charging of total 2 hours, in case of an ambient temperature less than 5°C

- 3Automatic extended charging of 2 hours in case of equalized charging.

- 4Automatic cutoff of AC input power in case of output power off in battery side.

- 5Temporary suspension of charging in case of phase losses in an input side such as black out and automatic return to charging in case of restoration of power supply

- 6Completion of charging when the battery terminal voltage gradually increases in case of low input alternating current voltage and total charging time exceeds 15 hours

- 7Completion of charging when the battery terminal voltage increases in case of high input alternating current voltage and the voltage reaches overcharge

- 8Stoppage of charging when an emergency stop switch is pushed

Equalized Charging Function

Equalized charging makes it possible to equalize the specific gravity of each cell by pushing "Equalized Charging" button.

Supplementary Charging Function in Winter Time

Micom solves the insufficiency of operation time due to decrease of solution temperature of the battery in a cold district by detecting an external temperature. (Extended charging of 2 hours in case of an ambient temperature less than 5°C)

Emergency Stop Switch

- 1The charging is temporarily stopped when an emergency stop switch is pushed, and all LED lamps give notice of emergency stop while switching on and off simultaneously

- 2All LED lamps are put out when the emergency stop switch is pushed again in the above status.

- 3In case of cancellation of the emergency situation and resumption of the charging in the above status, it returns to the charging when the emergency stop switch is pushed again.

Charging History Management

By connecting PC to a charger, you can read charging data on your PC, which has been recorded in the memory of control board inside the charger for over 512 cycles (for about 2 years), such as voltage, current, charging amount, charging date and time, and basic data of normal/abnormal charging. This data can be utilized for maintenance.

Charger Specification

Charger Specification

| Model | Battery Voltage | Input Voltage | Chargeable Battery capacity (Ah/5hr) |

|---|---|---|---|

| BMF 230 | DC 48V | AC 220V | 210-250 |

| AC 380V | |||

| AC 440V | |||

| BMF 295 | DC 48V | AC 220V | 280-335 |

| AC 380V | |||

| AC 440V | |||

| BMF 365 | DC 48V | AC 220V | 340-385 |

| AC 380V | |||

| AC 440V | |||

| BMF 460 | DC 48V | AC 220V | 400-490 |

| AC 380V | |||

| AC 440V | |||

| BMF 540 | DC 48V | AC 220V | 500-600 |

| AC 380V | |||

| AC 440V | |||

| BMF 650 | DC 48V | AC 220V | 610-690 |

| AC 380V | |||

| AC 440V | |||

| BMF 740 | DC 48V | AC 220V | 700-770 |

| AC 380V | |||

| AC 440V | |||

| BMF 840 | DC 48V | AC 220V | 800-870 |

| AC 380V | |||

| AC 440V |

Structure

Structure

This charger has a silicon rectifier, a leakage transformer, a magnetic contactor and a controlling print board inside and an operation panel is equipped on the front. Moreover, the small size, high-performance and unexposed electric components make it possible to place the charger even in a narrow space.

Rating

Rating

| Charger type | Battery voltage | Capacity of charged battery (AH/5HR) |

Size W x L x H |

Weight (Kg) |

Capacity of output fuse (A) |

|---|---|---|---|---|---|

| BMF 230-48 | 48 | 210~250 | 400 x 420 x 360 | 59 | 100 |

| BMF 295-48 | 280~335 | 65 | 100 | ||

| BMF 365-48 | 340~385 | 69 | 100 | ||

| BMF 460-48 | 400~490 | 460 x 480 x440 | 75 | 150 | |

| BMF 540-48 | 500~600 | 80 | 150 | ||

| BMF 650-48 | 610~690 | 90 | 200 | ||

| BMF 740-48 | 700~770 | 480 x 520 x460 | 97 | 250 | |

| BMF 840-48 | 800~870 | 107 | 250 |

* A separate specification applies to battery voltages of 24, 36, 72 and 80V

Input Current and Setting Values of Over-Current Relay (OCR)

Input Current and Setting Values of Over-Current Relay (OCR)

| Type and capacity of charger | Input voltage and current | Setting values of overcurrent relay | ||||

|---|---|---|---|---|---|---|

| 220V | 380V | 440V | 220V | 380V | 440V | |

| 230AH | 11.0A | 6.5A | 5.5A | 13.0A | 7.5A | 6.0A |

| 295AH | 14.5A | 8.5A | 7.0A | 16.0A | 9.0A | 9.0A |

| 365AH | 17.5A | 10.0A | 9.0A | 19.0A | 11.0A | 9.0A |

| 460AH | 22.5A | 13.0A | 11.0A | 24.0A | 13.0A | 11.0A |

| 540AH | 26.0A | 15.0A | 13.0A | 28.0A | 16.0A | 13.0A |

| 650AH | 30.3A | 17.5A | 15.1A | 39.4A | 22.8A | 19.7A |

| 740AH | 30.0A | 20.0A | 17.5A | 39.0A | 24.0A | 20.0A |

| 840AH | 40.0A | 22.0A | 20.0A | 45.0A | 24.0A | 22.0A |

Specification

Specification

| Ambient temperature | -10 ℃~+40℃ |

| Ambient humidity | Under 90% RH |

| Pressure resistance | AC 1500V/minute |

| Insulation resistance | More than 10MQ at DC 500V mega |

| AC input power | AC 200V~240V / 360V~400V / 420V~460V, 50/60Hz |

| DC output power | DC46V ~ 68V (while in normal charging) |

| Charging time | About 8 hours (In case of 80% discharge rate) |

Semi-constant Voltage/Semi-Constant Current Type

Semi-constant Voltage/Semi-Constant Current Type

This charger is controlled by micom to have a charging property of [output voltage] and [output current] using a leakage transformer. Therefore, the charging is completed by automatically determining the charging amount even in case of charging an irregularly discharged battery.

Satisfaction of Overseas Customers' Demand (SHINKO FORKLIFT / SUMITOMO NACCO)

Satisfaction of Overseas Customers' Demand (SHINKO FORKLIFT / SUMITOMO NACCO)

| Ambient Temperature | -10˚C ~ +40˚C |

| Ambient Humidity | Under 90% RH |

| Proof Pressure | AC 1500V/minute |

| Insulation Resistance | More than 10MΩ at DC 500V mega |

| AC Input Power | AC 200V~240V/ 360V~400V / 420V~460V, 50/60Hz |

| DC Output Power | DC 46V~68V(while in normal charging) |

| Charging Time | About 8 hours (in case of 80% discharge rate) |

| Normal Charging | over 3,000 cycles |

| Supplementary Charging | Supplementary Charging |

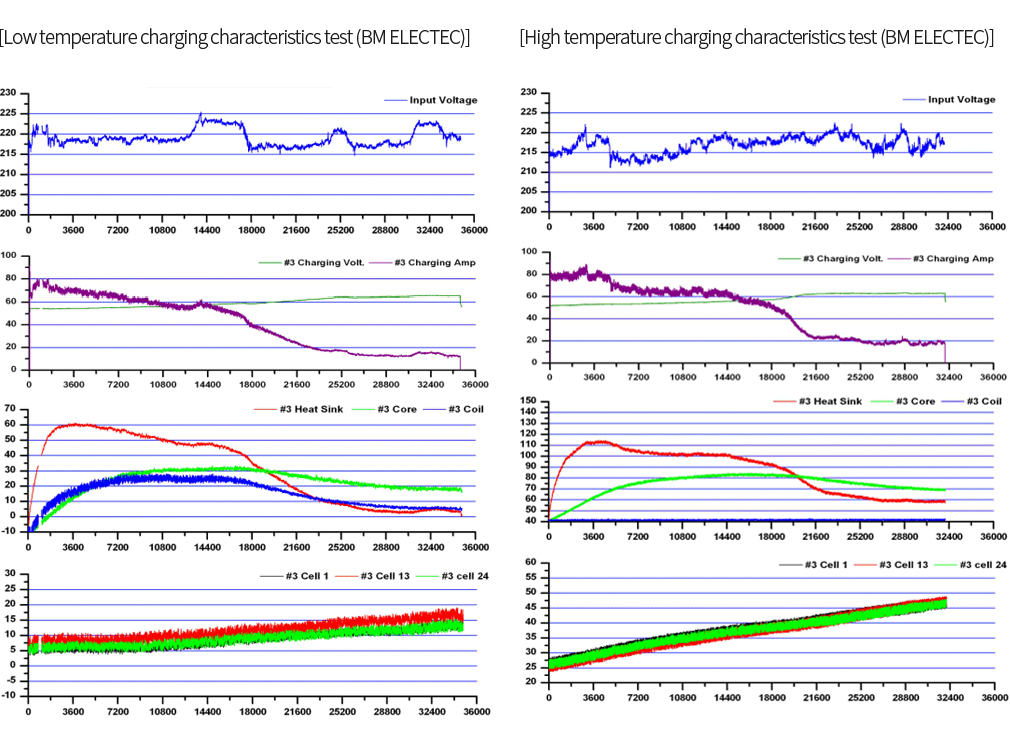

Test Result by Doosan Infracore Co., Ltd. R&D Dept.

Test Result by Doosan Infracore Co., Ltd. R&D Dept.

- Low-temperature charging property (ambient temperature -100): weight of battery after completion of charging 1.29-1.30(full charged) (weight in case of 25C conversion: 1.28)

- Low-temperature charging property (ambient temperature -100): weight of battery after completion of charging

- High-temperature charging property (ambient temperture +40C): weight of battery after completion of charging 1.27-1.28(full charged) (weight in case of 25C conversion: 1.28)

- Type of this charger in case of test : BDW-460-48-220

- Specification of battery in case of test : 48V-440AH-5HR

- Moreover, the charger has acquired the most excellent evaluation on temperature of components in the charger, noise, charging time, etc